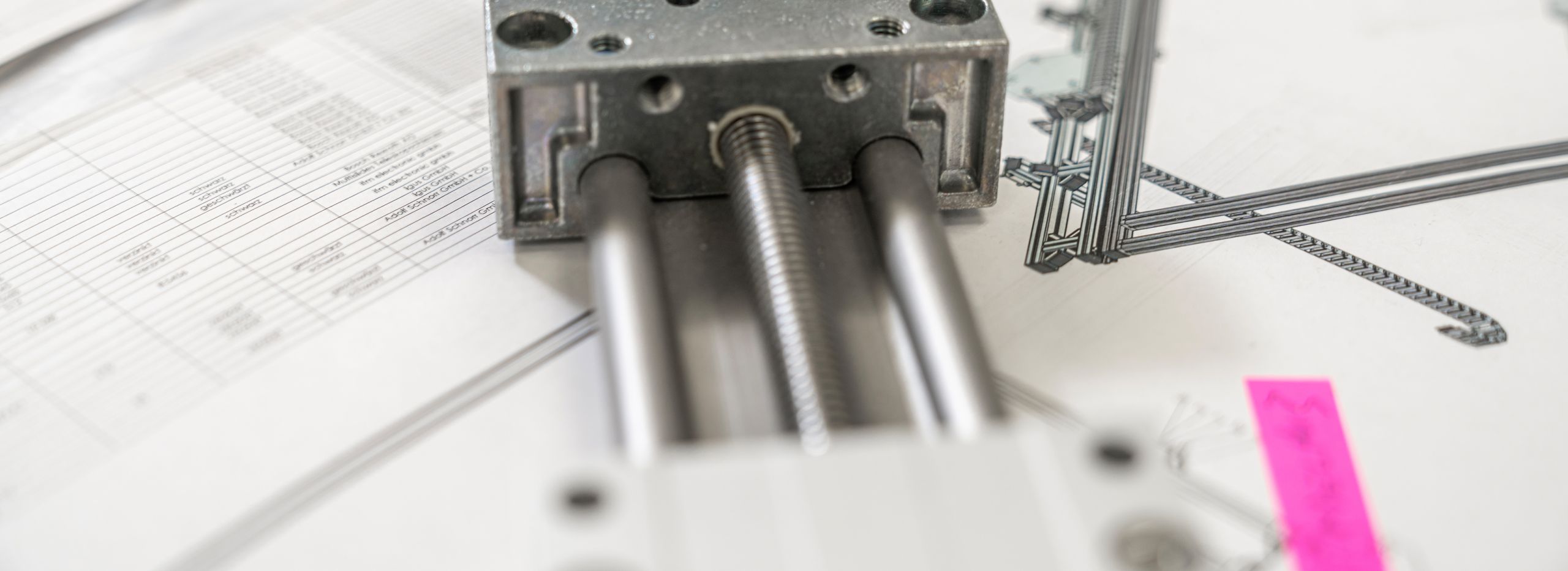

Robots in automated test systems increase productivity and precision

As an experienced testing technology provider with over 30 years of experience, we know how important precise and reliable testing is for your quality standards. The use of robots in testing technology is becoming increasingly important for complex tests and more productivity. Let's take a look at the future of testing technology and discover what opportunities are available through the use of robots.

Our team offers you extensive experience and expertise - including the use of inspection robots. For an initial consultation, simply call: +49 9342 - 933 90. Or write an office wsk-elektronik.de (e-mail).

wsk-elektronik.de (e-mail).

Robots for your test facility

Robot assisted testing system?

As a manufacturer of testing equipment we offer you:

- Planning and development of robotic, automated testing systems

- Robots for industrial requirements and demanding environments

Please send specifications

Simply send us your specifications and get a quote.

If you do not yet have a specification sheet, we will be happy to assist you with the conception and preparation of your specification sheet.

Receive a quick quote

Our tasks for the construction and programming of your robotic testing system are clearly described?

Then you will receive a transparent, fair offer shortly.

Do you have a complete set of specifications? Then get a quote directly.

You do not have a complete specification sheet yet? Then please arrange a meeting.

6 simple steps to a robotic testing system

Create concept

Your and our experience combined, form the foundation for the cooperation. Let's start with the concept for your individual cobot!

Plan plant

In close coordination with your team, our specialists perform their tasks in electrical engineering, electronics, programming and device construction.

Build plant

The construction of your test facility begins - accompanied by meaningful tests and in consultation with you. The well-coordinated team works efficiently and with motivation.

Software

When it comes to software, we often fall back on tried-and-tested modules. This saves development costs. We reprogram according to specific needs.

Commissioning

The test runs were successful. Your robot-assisted system is ready for use and is only waiting to be commissioned at your site.

Briefing

On time, we commission your robot-assisted system at the desired location, instruct your team and answer questions.

Advantages of testing robots

- Precision: Testing robots perform tests and inspections faster and more precisely than human inspectors.

- Consistency: Testing robots work accurately and reproducibly. Thus, they support the delivery of accurate test results.

- Efficiency: Robots can move test specimens quickly, shorten setup times, and bring measuring devices close to test specimens.

- Safety: Inspection robots can be used in hazardous or hard-to-reach environments to ensure human safety.

- Health: Testing robots perform stressful, repetitive motions.

Examples of applications for test robots and cobots

Robots and cobots in testing technology increase productivity, increase precision and reduce costs. Robots perform their movements quickly and efficiently. In contrast, slower-working cobots focus on safety when working with humans.

Cobots can help improve the safety of human inspectors by performing dangerous or difficult inspections. Cobots represent effective collaboration and combine the advantages of human and machine intelligence.

Robots in the automotive industry

In the automotive industry, robots are used in assembly inspection, surface inspection, end-of-line testing and defect identification. They can perform functional tests on components or carry out endurance tests.

Robots in the medical device industry

In the medical device industry, robots perform visual inspections. They complete dimensional checks, load tests, leak tests, functional tests, electrical tests and durability tests using the appropriate measuring equipment. They can also be used in the inspection of packaging.

Robots for food industry

In the food industry, robots are used to check packaging. Here, they can use the appropriate measuring devices to check, for example, whether the weight, size or quantity of the products in the packaging are correct.

Robots in mechanical engineering

In the engineering industry, robots are used in assembly inspection, surface inspection and defect identification. They can also be used in quality control to ensure that products meet requirements.

This is how your robotic testing system is created

Several pieces of information are needed to build your custom robotic testing system. Below are some important aspects for a concept with testing robot:

In order to optimally adapt your robot or cobot to the testing process, the requirements for the process must be discussed in detail. In the process, we clarify what type of tests are to be performed, what test criteria exist and what test conditions prevail.

In order to optimally adapt your robot or cobot to the test specimen, information should be available on its size, shape, weight and material properties. Any special features such as sensitive surfaces or complex geometries are also taken into account.

Information about the environment of the test facility in which the robot or cobot is to be used is also important. For example, the room size, ambient temperature, humidity and the presence of dust, dirt or other influences should be determined.

Depending on the test process, different requirements can be placed on your robot or cobot. Here, it should be clarified which movements are to be executed, which gripping tools are required and which sensors are available.

Since a cobot in automated testing technology is used in close proximity to humans, safety is a key issue. Information about the necessary safety measures and precautions should therefore be included from the very beginning.

We determine this information during consultation meetings with you. In close cooperation, the requirements for your robotic testing system can be determined and implemented in a suitable concept. Just give us a call or write to us!